|

Unit 140 - 14480 River Road, Richmond

British Columbia, Canada,

V6V 1L4

Telephone: +1 604 273 6080

|

|

|

ROLL

POSITIONING:

Air Setworks Positioning System

|

|

The

purpose of the system is to control the roll pressure (position) based

on the incoming board/cant thickness. The Pneumatic Positioning System

utilizes a Royal TR Series designed pneumatic actuator with

integrated Temposonics probe for position feedback.

This is an economical solution for

driving pneumatic cylinders moving rolls in closed loop

control. This positioning system is also used on

pickers and side rolls.

|

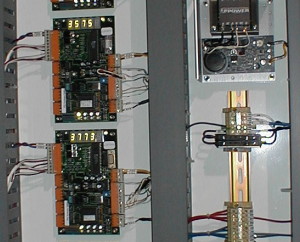

The system is comprised of:

- Controller Board (one card per

roll axis) - usually all of the boards required for the

machine are mounted in an enclosure complete with power

supplies.

- Proportional Valves assembly

(two valves per axis). The pneumatic valves are proportional

control devices that are driven in tandem to maintain

constant control and keep rigidity of the object being

driven. The software settings allow the user to adjust

position and force parameters. The control of either force

or position can be switched on the fly giving seamless

transition between the two. This system helps to

reduce/prevent damage to the roll, material being processed

and the machine structure in typical roll applications.

- Temposonics Probe integrated

into the Royal Cylinder assembly, which is connected

to the customer's pressroll. Typical systems in the field

use 3 inch Bore cylinders moving rolls weighing up to 1000

lbs.

- Linear Displacement Optical Lasers

for measurement of incoming cants/boards.

- Interface to subroutine within

customer's PLC for generation of position command signals.

The loop is closed by use of the controller which receives

an 0 -10 VDC analog command signal from the PLC.

|

|

|

|