|

|

|

Unit 140 - 14480 River Road, Richmond

British Columbia, Canada,

V6V 1L4

Telephone: +1 604 273 6080

Fax: +1 604 273 6180

|

|

Optimum Lumber Trimmer System

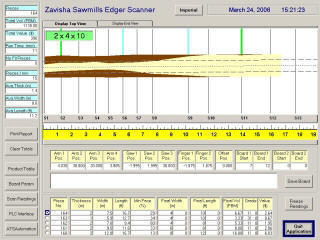

The scanner system measures the thickness, width and length of each board passing transversally through the scanner heads, calculates the volume and wane and concludes the best trimming solution. The trimming solution is sent to a PLC for board tracking, trimmer positioning and saw control. The scanner system also includes a dedicated computer for data collection and report generation.

|

||

The scanner solution includes the positions of the setworks axes during the processing of the board to recover the best value product. The computer sends this edging solution to the PLC for actual positioning and tracking.

|

||

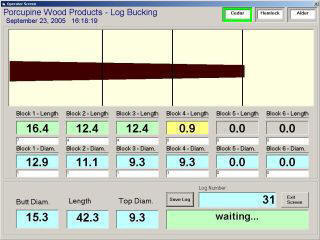

Optimized Log Bucking System

The Optimized Bucking System determines the diameter, length and volume of each scanned log, and concludes the best recovery log bucking solution and sort destination for every future cut piece that is then sent to the PLC for cutting and further tracking. The system stores the production data for shift and history report generation. |

|

ATS Automation Inc. -

ATS © 2011 |